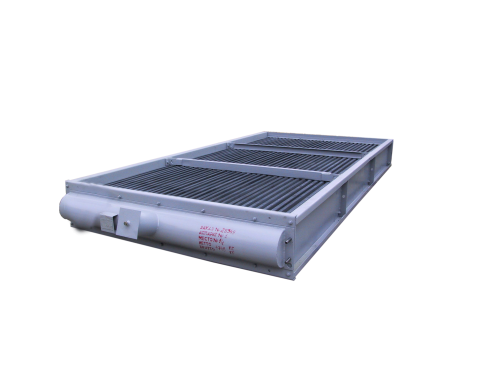

The plant started manufacturing condensers and a dephlegmators with finned tubes oval section 55х18х1,7 steel B-10, B-20.

These devices are used for the condensation of turbine steam (condensers) and removal of non-condensable gases (dephlegmator). For mounting dimensions and technical parameters they fully comply with the sections produced by GEA company.

The plant has mastered almost all sizes for use in vacuum - extractors of compressors 101-JC, 102-JC and 103-JC, 104-JC

Характеристики

| # | Specification | 101-JC | 102-JC | 103-JC |

| 1 | Total steam consumption vacuum extract (from three turbines), t/hour | 135 | 135 | 135 |

| 2 | Total heat exchange surface, m2 | 37480 | 12534 | 57330 |

| 3 | Overall dimensions, mm

Capacitors length L width B height H dephlegmators length L width B height H |

5250

2695 530 5050 2695 530 |

4250

2270 530 4050 2275 530 |

6250

2500 530 6050 2500 530 |

| 4 | Product | Water steam | Water steam | Water steam |

| 5 | Vacuum, ATM. | 0,32 | 0,32 | 0,32 |

| 6 | The product temperature at the turbine outlet, °C | 70,2 | 70,2 | 70,2 |

| 7 | The product temperature at the inlet of condensate, °C | 67,0 | 67,0 | 67,0 |

In order to increase the thermal contact between the ribs and pipes, each pipe assembly is painted with a zinc-containing paint containing up to 99% Zn in the dry coating layer. Upon customer request, thermal contact can be provided by hot-dip galvanizing.

The devices comply with all the requirements for the device and the safe operation of vessels working under pressure from the State labor protection supervision department of Ukraine and the State mining supervision department of the CIS countries.

If necessary, sections can be made corresponding to sections 105-JC, 106-JC, 107-JC of the company GEA.